- Tel: +8617353839397

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

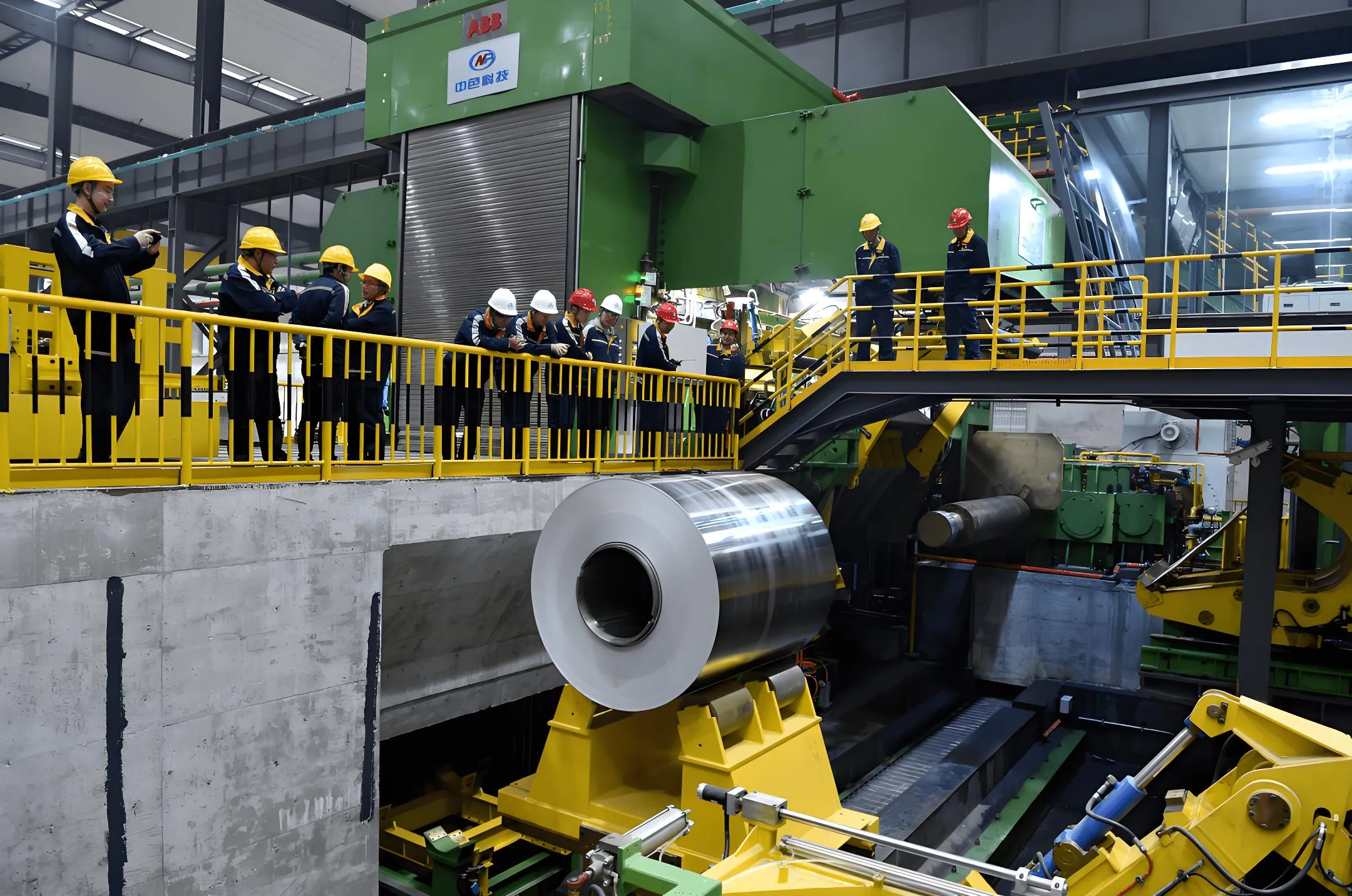

Stainless steel coils are an important type of metal material. They are made from stainless steel plates through the winding process. They have excellent corrosion resistance, strength and toughness. Their surfaces are smooth and tidy and can be cut and processed into various products according to demand. They are widely used in many fields such as construction, manufacturing, kitchenware, etc., and are indispensable materials in modern industry.

![]() Whatsapp :+86 17353839397

Whatsapp :+86 17353839397

![]() Email : [email protected]

Email : [email protected]

| Product Name | Stainless Steel Coil |

|---|---|

| Length | as required |

| Width | 3mm-2000mm or as required |

| Thickness | 0.1mm-300mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

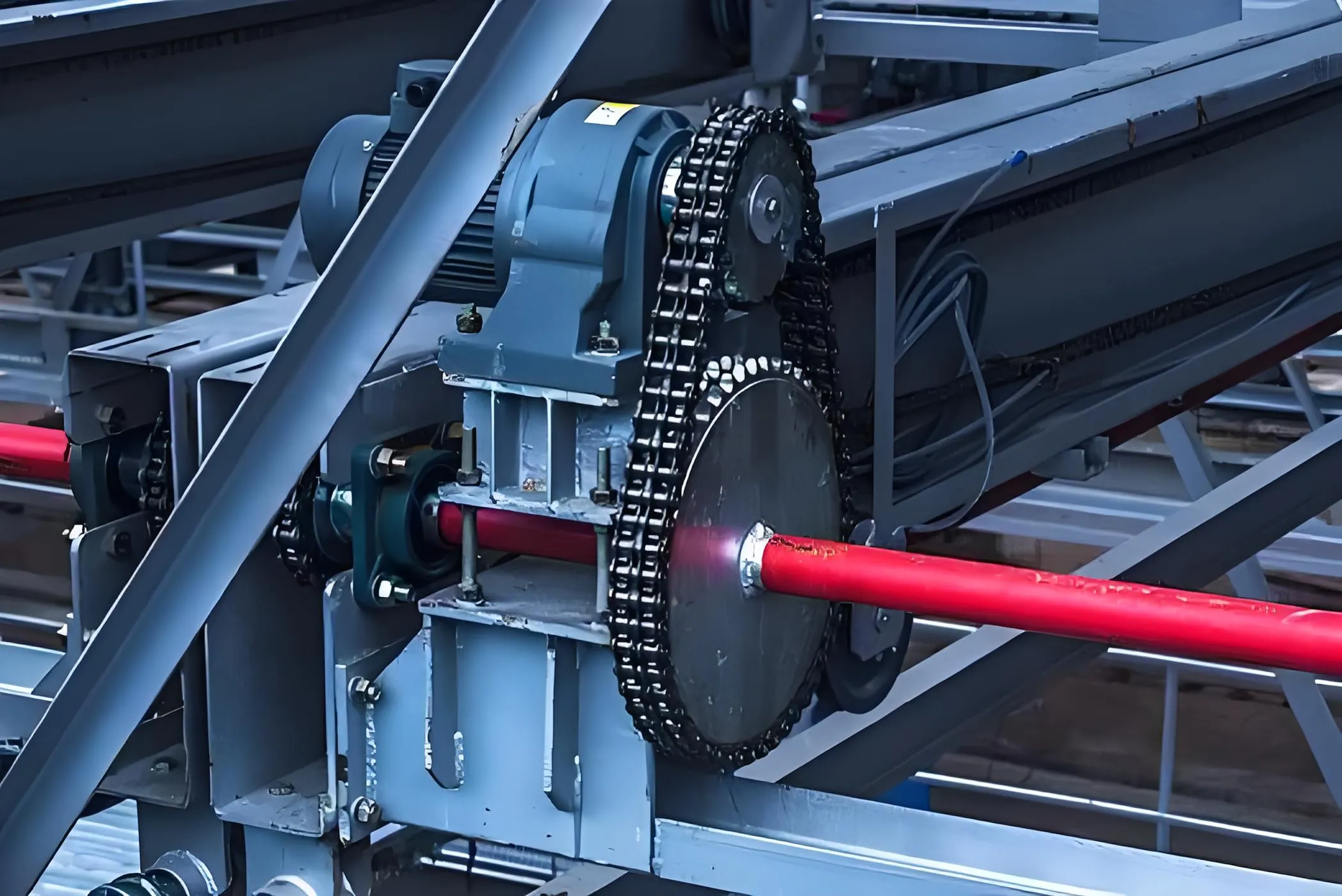

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 25tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

1. Density: Usually around 7.93 grams per cubic centimeter, relatively high.

Melting point: generally between 1398 and 1454 degrees Celsius, depending on the composition of the stainless steel.

3. Thermal conductivity: Thermal conductivity is relatively poor, with a thermal conductivity of about 16.3 to 37.1 W/(m · K).

4. Conductivity: It has a certain degree of conductivity, but it is not as good as metals such as copper and aluminum.

5. Magnetic: Most stainless steel coils are non-magnetic or weakly magnetic at room temperature, but some types may be magnetic during processing or under specific conditions.

1. Corrosion resistance: This is one of the most important chemical properties of stainless steel coils. It can resist corrosion in the atmosphere, water, acid, alkali and other environments.

2. Oxidation resistance: It can resist oxidation in high temperature environments and maintain surface integrity and performance. For example, in high temperature industrial production environments, equipment made of stainless steel rolls can run for a long time without being severely oxidized.

3. Stability: The chemical composition of stainless steel coils is relatively stable and does not easily react with other substances. However, chemical changes may still occur in some strongly oxidizing media or under specific conditions.