- Tel: +8617660708369

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

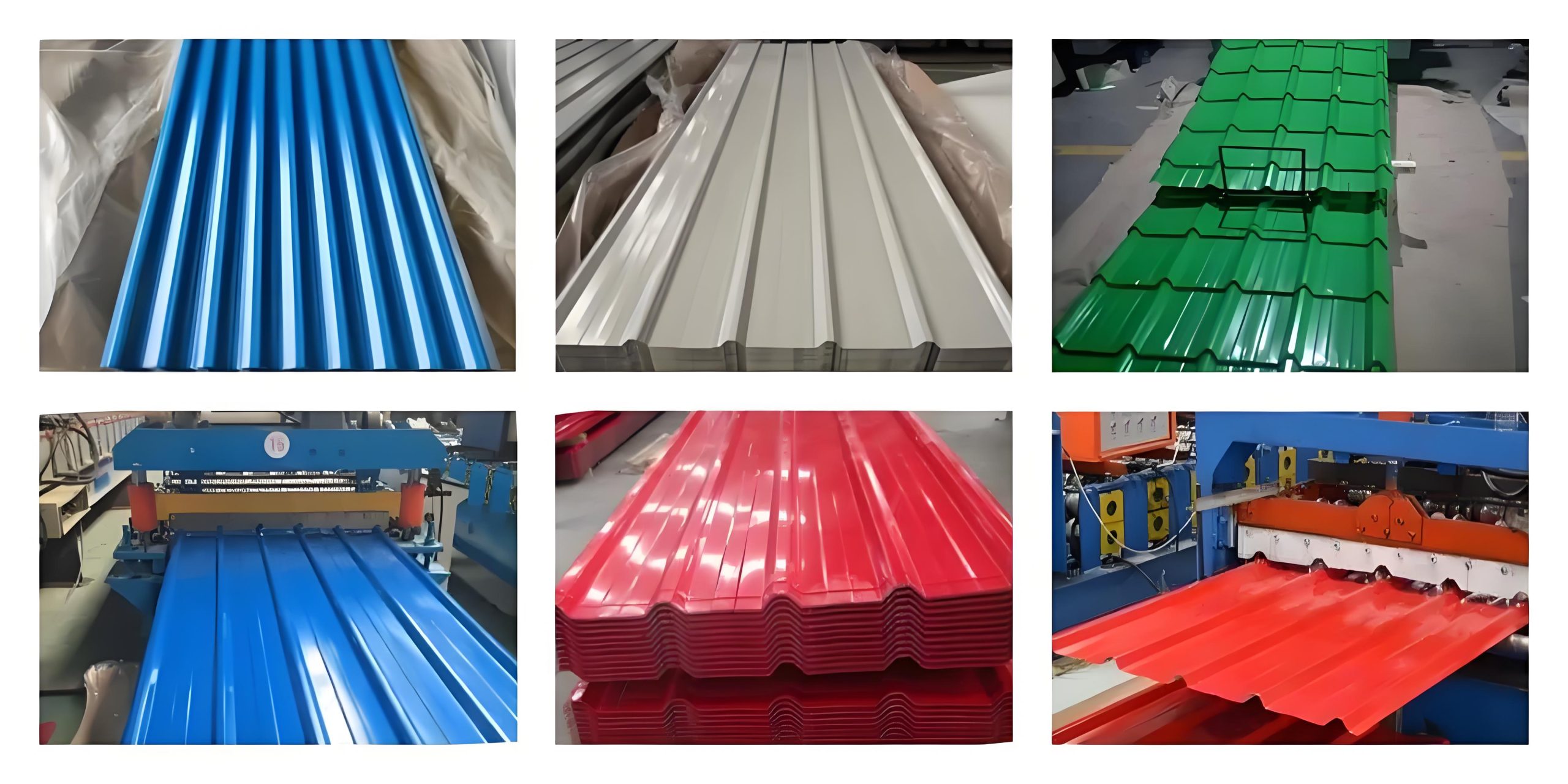

Color-coated sheet is a kind of metal composite material that applies organic coatings on the surface of steel plates. It has advantages such as bright colors, good appearance and durability, and anti-corrosion. It is often used in fields such as the exterior walls of buildings, interior decoration, and the shells of household appliances. For example, the walls of factory buildings and the side panels of refrigerators. Its performance is stable and it can adapt to different environments. It is one of the commonly used materials in modern industry and life.

![]() Whatsapp :+86 17660708369

Whatsapp :+86 17660708369

![]() Email : [email protected]

Email : [email protected]

| color coated galvanized corrugated roofing sheet | |

|---|---|

| Name | |

| color coated corrugated roofing sheet | |

| Material | |

| SGCC,SGCH,JIS G3302,DX51D,DX52D,DX53D | |

| Thickness | 0.10 -1mm |

| Width | 600-1100 mm |

| length | 2-5 meters |

| Tolerance | Thickness: +/-0.02mm |

| Width:+/-2mm | |

| Color coating | |

| Zinc Coating: 30g/m2-275g/m2 | |

| Color Coating: Top:15-25µm / Back: 5-8 µm | |

| Surface treatment | unoil,dry,chromate passivated, non-chromate passivated |

| Certification | ISO 9001-2008,SGS,CE,BV |

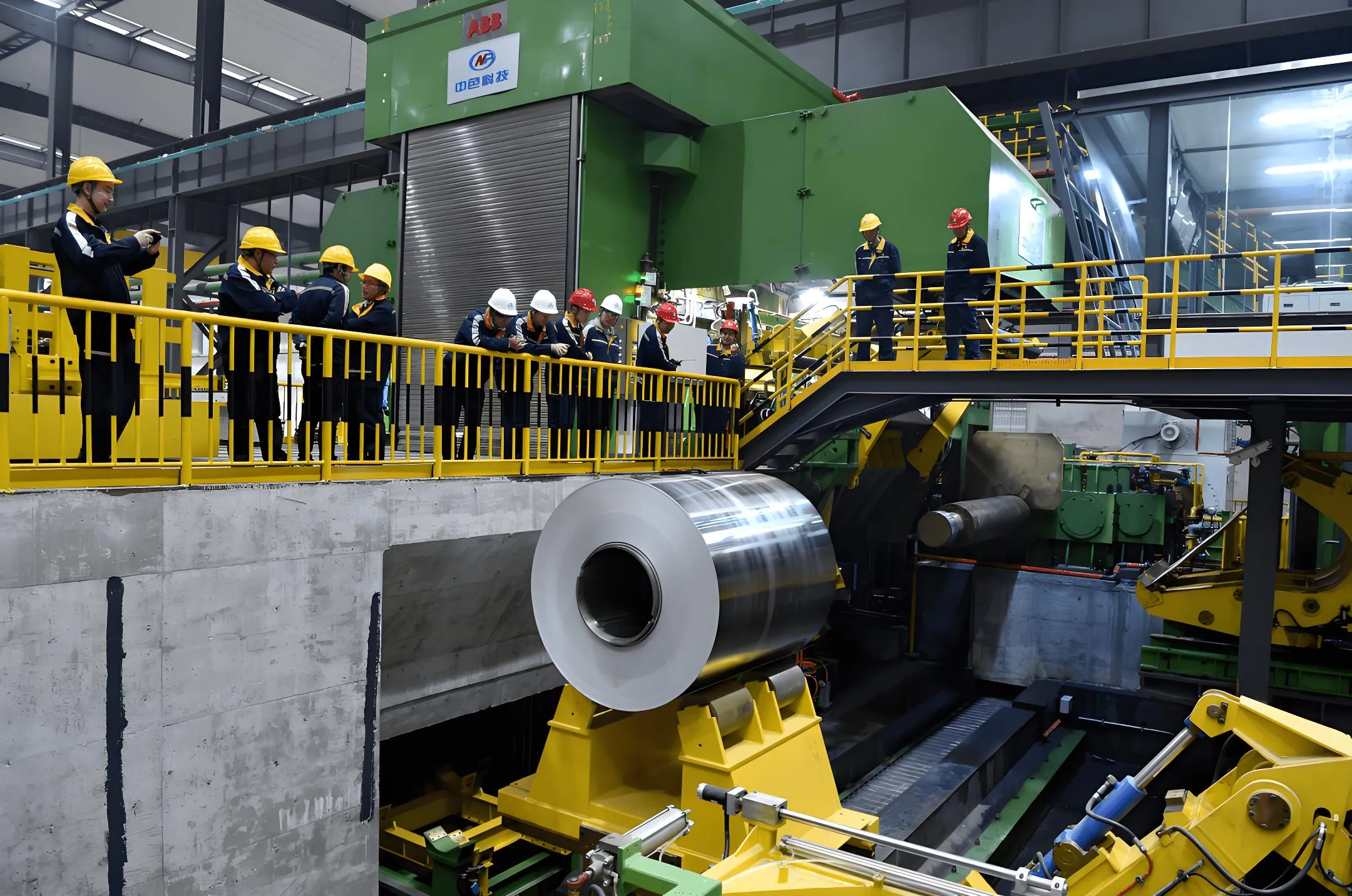

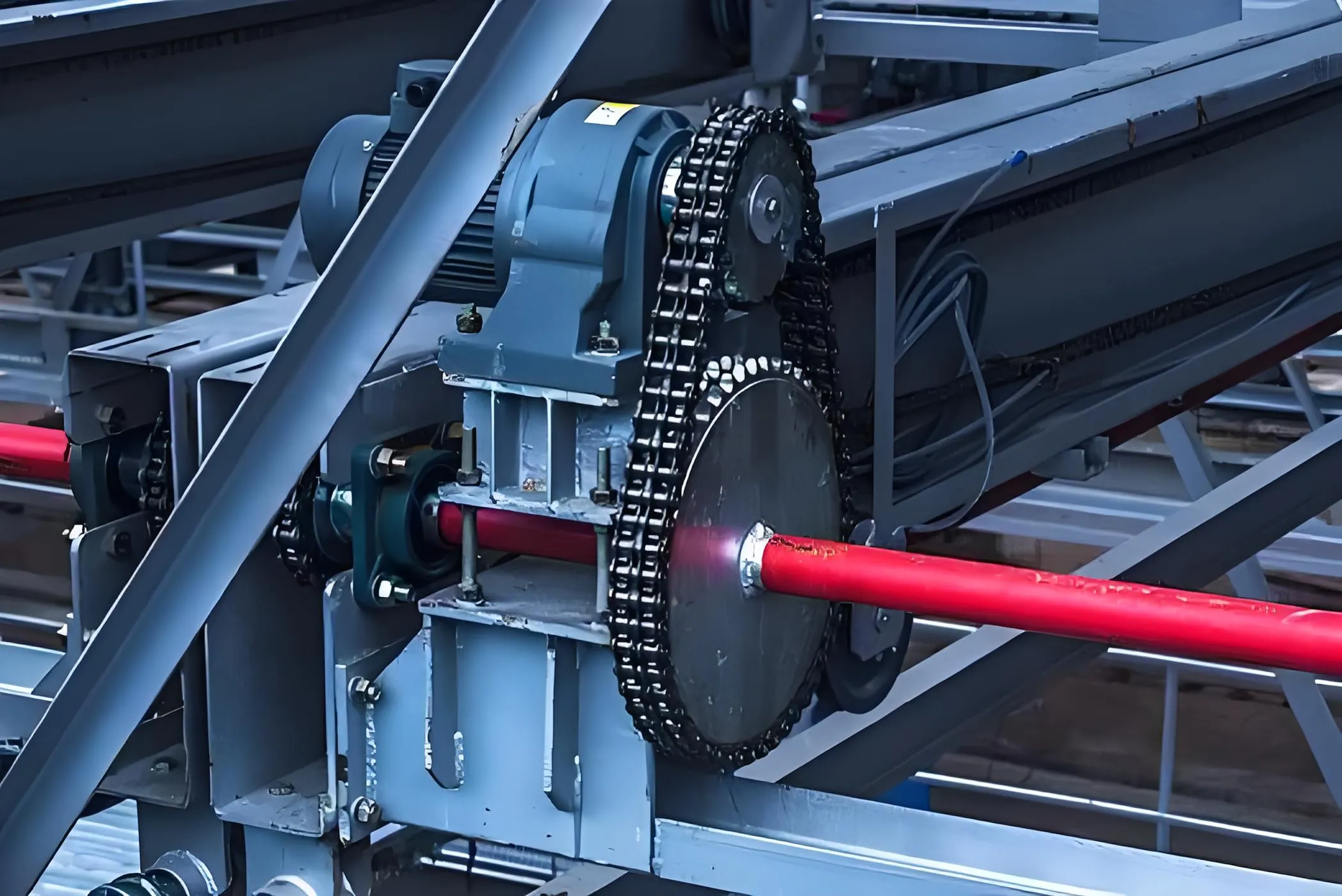

| Technique | Cold rolled—>hot dipped galvanizing—>Color Coated —> corrugated |

| Weight of each package | ISO 9001-2008,SGS,CE,BV |

| Depth of corrugated | from 15mm to 18mm |

| Pitch | from 75mm to 78mm |

| Colors | refer to RAL numbers or customer sample,common colors are sea blue, white grey and bright red. |

| Corrugated Sheet Raw | Galvanized steel, Aluzinc Steel, Aluzinc Pre-painted sheet and |

| Materials | Aluminium sheet. |

| Gloss | The gloss can changeable by Customers’ Request.we can also do some High gloss. |

| Paint type | PE or PVDF |

| Standard | GB/T 12754-2006;ASTM A 755;EN 10169;JIS G 3312;AISI;BS;DIN |

| Grade | CGCC/SGCC/SGCH/SPCC |

| Yield strength | 550MPA/As required |

| Tensile strength | 600MPA/As required |

| Hardness | Full hard/soft/As required |

| Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

1. Mechanical Properties – Strength: Color coated plates usually have a certain strength and can withstand certain loads and external forces.

Ductility: Have a certain degree of ductility, so that it is not easy to break during processing and molding. – Hardness: The surface hardness is moderate to ensure that it is not easy to be scratched during use.

2. Coating Adhesion – The adhesion between the coating and the substrate is strong and not easy to peel off.

3. Surface Flatness – The surface is flat and smooth, which is conducive to aesthetics and subsequent processing.

4. Coefficient of Thermal Expansion – There will be a certain degree of expansion when heated, which needs to be considered in the design and use.

1. Corrosion Resistance – The coating on the surface can effectively resist the erosion of corrosive substances such as oxygen, moisture, acid rain in the atmosphere. – It also has certain tolerance to acids, alkalis, salts and other chemicals.

2. Oxidation Resistance – It is not easy to oxidize in the air, maintaining the stability and color of the surface.

3. Weather Resistance – It can withstand long-term sunlight exposure, temperature changes and climate changes to maintain stable performance.