- Tel: +8617353839397

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

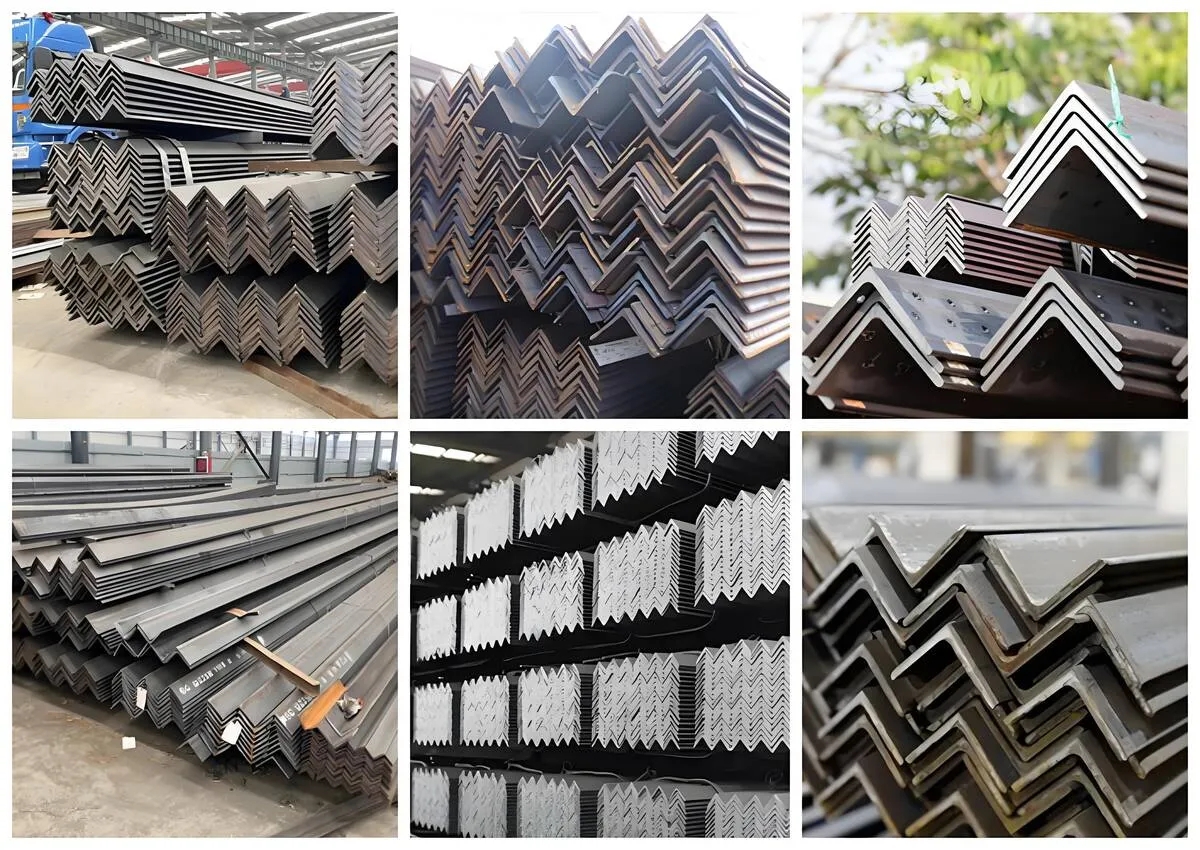

Carbon steel angle, a high-quality metal material. It is made of high-quality carbon steel, with high strength and good hardness. Its corners are regular, the size is precise, and the surface is smooth. It has good wear resistance and toughness, and is suitable for structural support and connection in fields such as construction and machinery. Rust prevention treatment makes it more durable and is a reliable choice for engineering construction.

![]() Whatsapp :+86 17353839397

Whatsapp :+86 17353839397

![]() Email : [email protected]

Email : [email protected]

| Product | Carbon Angle Bar |

|---|---|

| Standard | JIS, AISI, ASTM, GB, DIN, BS, etc. |

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C,Q390D,Q390E,Q420,Q420B,Q420C ,Q420DQ420E,Q460,Q460D,Q500C,Q500D,Q500E,Q550C,Q550D,Q550E,Q620C,Q620D, Q620E,Q690A,Q690B,Q690C,Q690D,Q690E,Q690D,Q690C,Q890C,Q890D,16Mo3,16MnL,16MnR ,16Mng,16MnDR |

| Size | 8*8*1-200*200*20mm*Length |

| Tolerance | +/- 1% |

| Sample | Available |

| Packing | Packing in bundle |

| Delivery time | Within 20 days after get the deposi |

1. Density:

Generally about 7.85 g/cm3, it belongs to the metal material with higher density, which determines that it has a larger mass under the same volume.

2. Strength:

It has a higher strength and can withstand a larger external force. Under different grades and heat treatment states, the strength will vary.

3. Elastic modulus:

It usually has a higher elastic modulus, which makes it less deformed and more resilient when stressed.

4. Thermal expansion coefficient:

The thermal expansion coefficient is relatively large, and the size change is more obvious when the temperature changes.

5. Magnetic:

Most carbon steel angles are magnetic, which makes it have certain applications in the electromagnetic field.

1. Flammability:

It can burn in a high temperature and aerobic environment.

2. Reaction with oxygen:

It is easy to oxidize with oxygen in the air to form rust (the main component is iron oxide), especially in a humid environment.

3. Reaction with acid:

It can react with strong acids such as hydrochloric acid and sulfuric acid to produce hydrogen and corresponding salts.

4. Surface treatment:

It can form a protective layer on its surface by surface treatment methods such as electroplating and electroless plating to change its chemical properties and improve corrosion resistance.