- Tel: +8617660708369

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

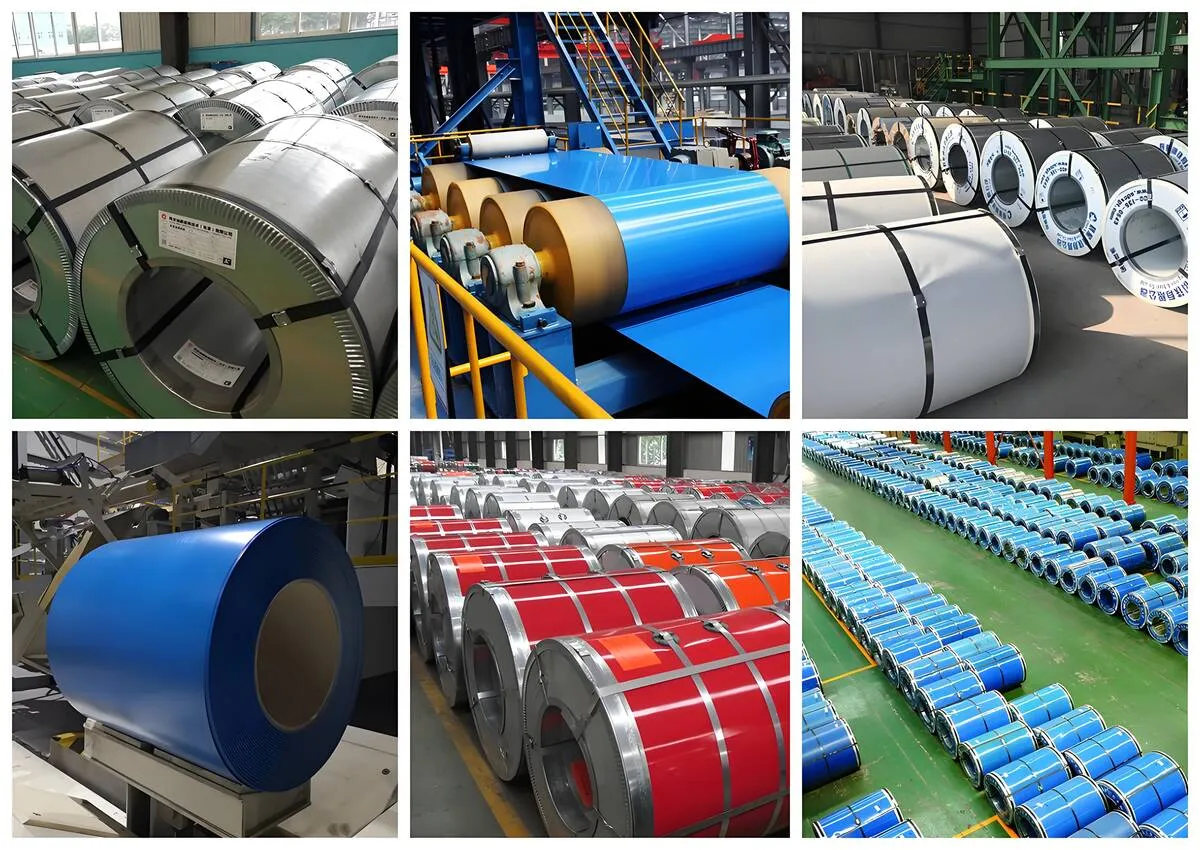

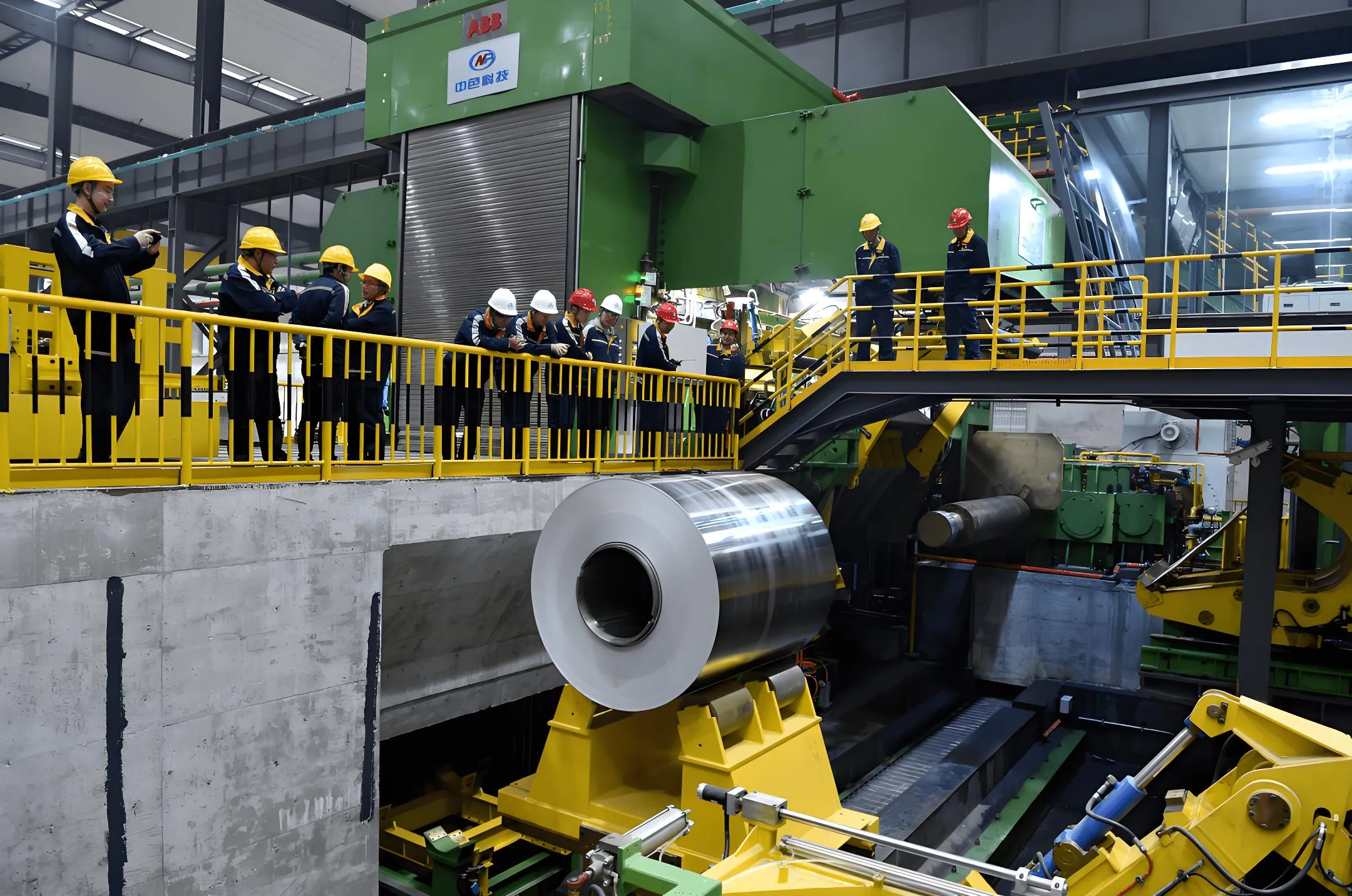

Color coated roll is a kind of metal coil with organic coating on the surface. It uses galvanized sheet, aluminized zinc sheet, etc. as the substrate, and imparts rich colors through the coating process. It has the advantages of beauty, rust prevention, corrosion resistance, etc., and is widely used in construction, home appliances, transportation and other fields. It is an indispensable material in modern industry and life.

![]() Whatsapp :+86 17660708369

Whatsapp :+86 17660708369

![]() Email : [email protected]

Email : [email protected]

| Product | Color Coated Coil |

|---|---|

| Length | as required |

| Width | 600-1500mm or as customer’s requirements |

| Thickness | 0.2-6mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Surface Treatment | Clean, blasting and painting according to customer requirement |

| Material | DX51D, S280GD, S350GD, SGCC etc |

| Spangle | Regular spangle, minimal spangle, zero spangle, big spangle |

| Application | Construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc. |

1. Strength: Color coated roll usually has a certain strength and can withstand certain external forces and loads. For example, when used in building roofs, it can withstand the action of natural forces such as wind and snow.

2. Hardness: It has moderate hardness and is not easy to deform, maintaining the stability of its shape and structure.

3. Ductility: It has certain ductility and can be bent and stretched moderately during processing. 4. Surface Flatness: The surface is relatively flat and smooth, which is conducive to beauty and subsequent processing and use.

1. Corrosion resistance: After special treatment, the surface coating can resist the erosion of oxygen, moisture, acid rain, etc. in the atmosphere and prolong the service life. For example, in the construction of coastal areas, it can resist the salt erosion brought by the sea breeze.

2. Oxidation resistance: The coating can effectively prevent the oxidation of the metal substrate and keep the performance of the material stable.

3. Chemical resistance: It has a certain tolerance to some common chemicals, such as cleaners, solvents, etc.

4. Heat resistance: In a certain temperature range, the performance of the coating and the metal substrate will not change significantly. But beyond a specific temperature, it may affect its physical and chemical properties.