- Tel: +8617353839397

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

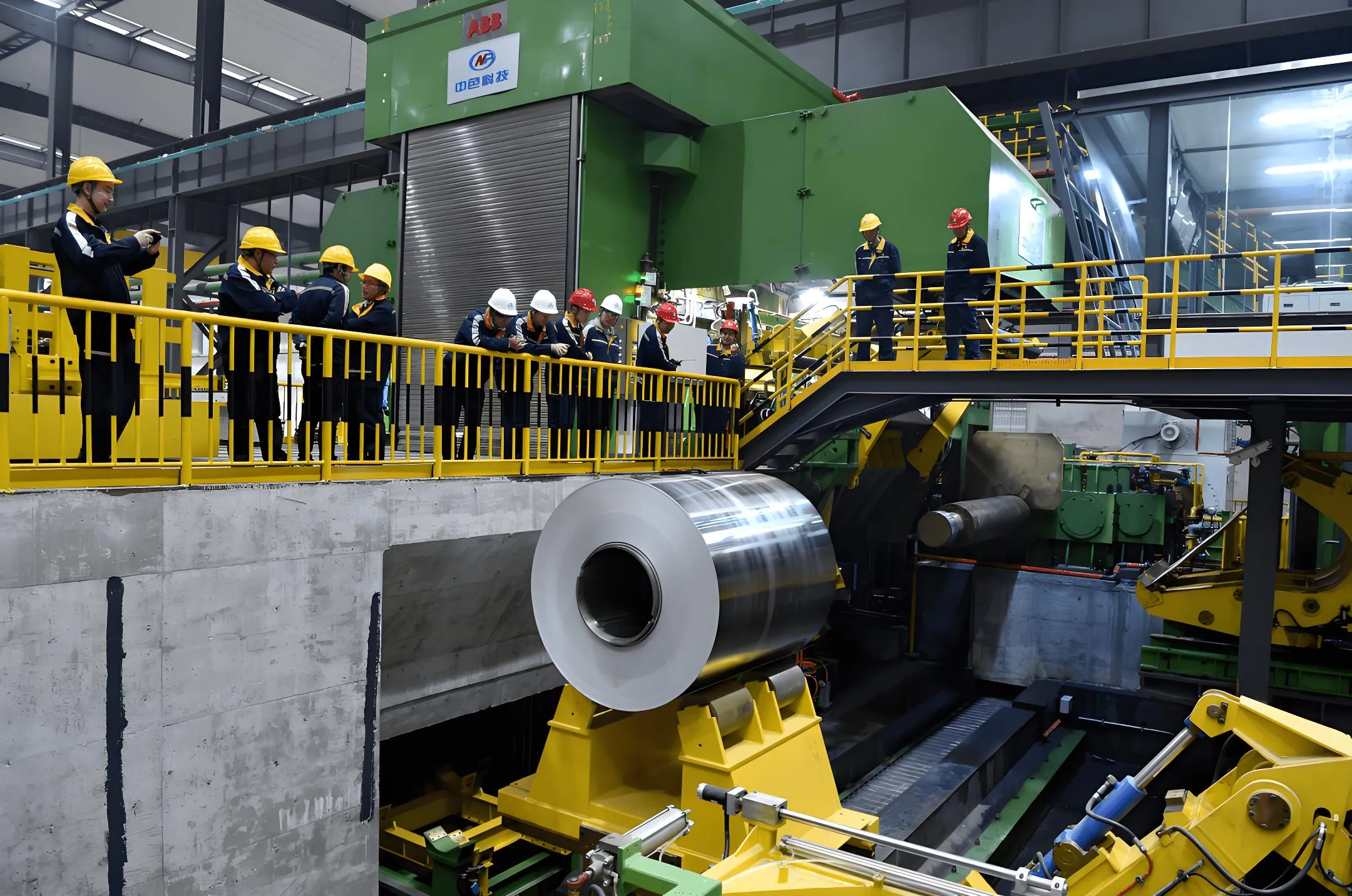

Aluminum coilis a rolled sheet of aluminum. It is lightweight, corrosion-resistant, and has excellent formability. Commonly used in various industries, it serves as a key material for manufacturing products like roofing, automotive parts, and packaging. Its conductive and thermal properties also make it suitable for electrical and heat transfer applications.

![]() Whatsapp :+86 17353839397

Whatsapp :+86 17353839397

![]() Email : [email protected]

Email : [email protected]

| Product Name | aluminum coil |

|---|---|

| Capacity | 1000 tons/month |

| Certifications | ISO 9001 |

| Material | 1000, 2000, 3000, 4000, 5000, 6000series a) 1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. b) 2000 Series: 2014, 2024, etc. c) 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. d) 4000 Series: 4045, 4047, 4343, etc. e) 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc. f) 6000 Series: 6061, 6063, 6082, 6A02, etc. |

| Thickness | 0.3-14mm |

| Width | 50-2000 mm |

| Coil Weight | 2-6 tons |

| Payment | 30% despoit in advance,70% balance before delivery |

| Application | 1)Further making utensil. |

| 2)Solar reflective film | |

| 3)The appearance of the building | |

| 4)Interior decorating:ceilings,walls,etc. | |

| 5)Furniture cabinets | |

| 6)Elevator decoraction | |

| 7)Signs,nameplate,bags making. | |

| 8)Decorated inside and outside the car | |

| 9)Household appliances:refrigerators,microwave ovens,audio equipment,etc. | |

| 10)The consumer electronics:mobile phones,digital cameras,MP3,U disk,etc. | |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)24-26CBM |

| 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM | |

| 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM | |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, etc. |

| Specification | Thickness≤30mm; Width≤2200mm Length≤12000mm OR Coil (C) |

| Application | Decoration, heat-sink device, external walls, storage, sheets for construction, etc. |

| Feature | Good rust resistance, not suitable for heat treatments, good corrosion resistant |

| performance, well welding property, good plasticity, low strength but suitable | |

| for cold working hardening |

Aluminum has a relatively low density, making aluminum coil lightweight. This property is advantageous in applications where weight reduction is crucial, such as in aerospace and automotive industries.

It is an excellent conductor of electricity, making it suitable for electrical wiring and components.

Allows for efficient heat transfer, used in heat exchangers and radiator systems.

Aluminum coil can be easily formed and shaped through various processes, enabling the production of complex designs.

Forms a thin oxide layer on the surface when exposed to air, providing some protection against further oxidation.

The oxide layer gives it good corrosion resistance in many environments. However, in highly acidic or alkaline conditions, corrosion can occur.

Can react with strong acids and alkalis, dissolving and releasing hydrogen gas.

Can be alloyed with other elements to enhance specific properties, such as strength and hardness.