- Tel: +8617353839397

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

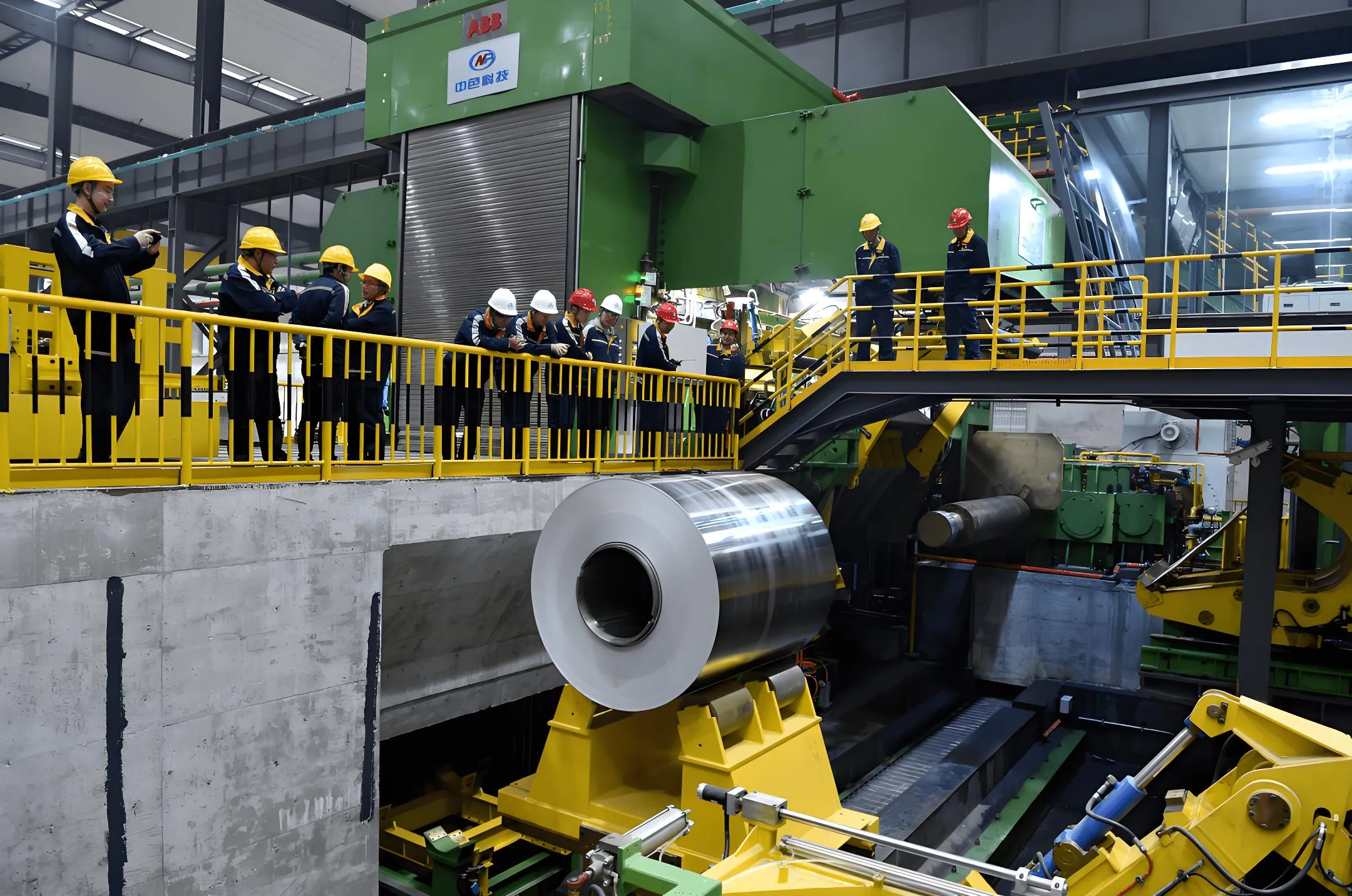

Carbon steel coil is a coil-shaped steel made from carbon steel. It has the characteristics of low cost and moderate strength. It is widely used in construction, manufacturing and other industries. It has good processing performance and can be made into products of different shapes and specifications through various processes to meet diverse needs. It is one of the commonly used basic materials in industrial production.

![]() Whatsapp :+86 17353839397

Whatsapp :+86 17353839397

![]() Email : [email protected]

Email : [email protected]

| Cold Rolled/ Hot Rolled Ms Carbon Steel Coils | |||

|---|---|---|---|

| Thickness | Hot Rolled Thickness:2.75mm-100mm, as Your RequestCold Rolled Thickness:0.2mm-3mm, as Your Request | ||

| Width | 1250-2500mm,or as Your Request ( regular width 1000mm, 1250mm, 1500mm ) | ||

| Coil ID | 508mm or 610mm | ||

| Coil Weight | 3 – 8 ton or as Your Request | ||

| Standard | ASTM EN DIN GB ISO JIS BA ANSI | ||

| Steel Grade | Q195, Q215,Q235,Q345,ST37, A36,45# ,16Mn, SPHC,SGCC,CGCC | ||

| Technique | Hot rolled cold rolled as Your Request | ||

| Surface Treatment | Bare,Black,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized,or as Your Request | ||

| Application | Applies to appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. | ||

| Package | Standard Export packing. | ||

| Payment Term | Pay 30%T/T deposit in advance, 70%T/T the balance before shipment.under $10,000, pay in full by T/T. | ||

| Remarks | Insurance per to Contract terms;MTC will be handed on with shipping documents;We accept the third party certificatation test. | ||

1. Hardness: Its hardness depends on the carbon content and heat treatment process. The higher the carbon content, the greater the hardness is usually. – For example, high-carbon steel coils have higher hardness and can be used to make wear-resistant parts such as knives.

2. Melting point: approximately between 1450 and 1500 ° C. – This requires specific conditions to ensure its performance during high-temperature machining.

3. Magnetic: Most carbon steel coils are magnetic. – Often used in the manufacture of components such as iron cores in electromagnetic equipment.

1. Reaction with acid: will react with strong acids (e.g. hydrochloric acid, sulfuric acid) and produce hydrogen gas. – For example, placing carbon steel coils in dilute hydrochloric acid will produce bubbles.

2. Easy to rust: It is easy to rust in humid air and generate iron oxide. – For example, the surface of carbon steel coil products exposed outdoors for a long time will rust.

3. Alloying can occur: It can form alloys with other metals or non-metallic elements, thus changing its properties. – Stainless steel can be made by adding elements such as chromium and nickel.