- Tel: +8617353839397

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Carbon steel channel steel, high-quality metal building material. Made of high-grade carbon steel, with excellent quality. Regular in shape, precise in size, and smooth on the surface. It has high strength, good toughness and compression resistance. Widely used in fields such as construction and machinery, it is a reliable choice for structural support. Rust-proof treatment makes it more durable and has high cost performance.

Category: Carbon steel channel steel

Key word: Carbon steel channel steel

![]() Whatsapp :+86 19353267125

Whatsapp :+86 19353267125

![]() Email : [email protected]

Email : [email protected]

| Length | 6m, 9m, 12m or as required |

|---|---|

| Thickness | 1.0mm-6.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

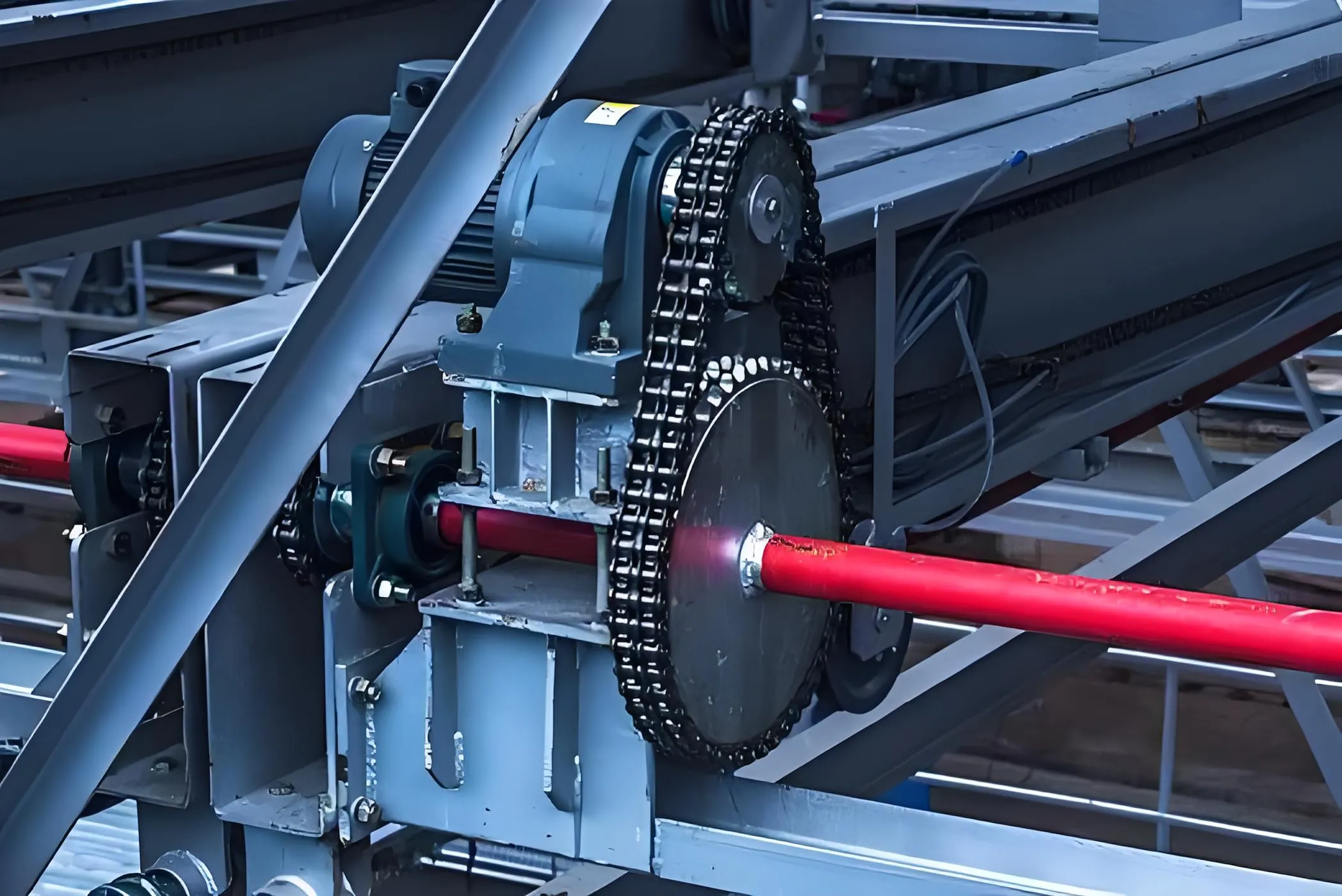

| Technique | Hot rolled |

| Surface Treatment | Clean, blasting and painting according to customer requirement |

| Thickness tolerance | ±0.1mm |

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C,Q390D,Q390E,Q420, Q420B,Q420C,Q420DQ420E,Q460,Q460D,Q500C,Q500D,Q500E,Q550C, Q550D,Q550E,Q620C,Q620D,Q620E,Q690A,Q690B,Q690C,Q690D, Q690E,Q690D,Q690C,Q890C,Q890D |

| 16Mo3,16MnL,16MnR ,16Mng,16MnDR | |

| HG785D,S690QL,50MN | |

| Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed. |

| Standard Export Seaworthy Package.Suit for all kinds of transport,or as required | |

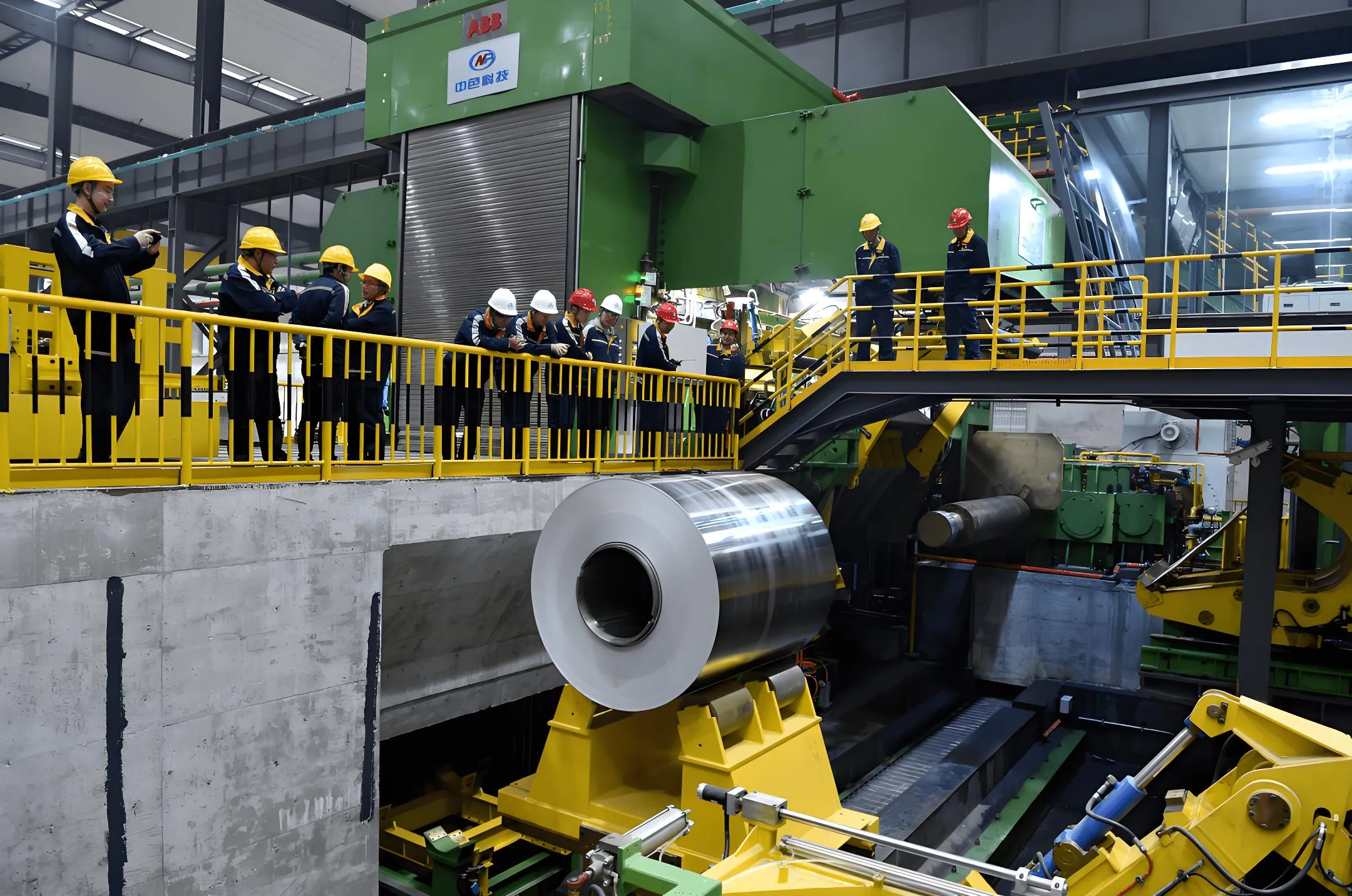

| Capacity | 250,000 tons/year |

1. Density:

about 7.85 g/cm3, which makes it have a larger mass under the same volume, increasing the stability of the structure.

2. Elastic Modulus:

has a high elastic modulus, when the force is relatively small deformation, can better maintain the shape and size of the structure.

3. Thermal Expansion Coefficient:

the thermal expansion coefficient is large, the size change is more significant when the temperature changes, this factor needs to be taken into account in the design and application.

4. Magnetic:

most carbon steel channel steel has magnetic properties, which makes it used in some applications that require magnetic properties, such as electromagnetic equipment.

5. Gloss:

the surface can show a certain luster after treatment, but not as bright as materials such as stainless steel.

1. Reaction with oxygen:

At room temperature, the surface will gradually oxidize with oxygen to form an oxide film, but in humid and high-temperature environments, the oxidation rate increases.

2. Reaction with acid:

It is easy to react and dissolve with strong acids such as hydrochloric acid and sulfuric acid to produce hydrogen and corresponding salt compounds.

3. Reaction with base:

Under certain conditions, it can react with strong bases, especially in high temperature and strong alkaline environments.

4. Electrochemical corrosion:

In the electrolyte solution, it is easy to form a primary battery, electrochemical corrosion occurs, resulting in damage to the material.

5. Alloying:

Alloying can be achieved by adding other elements, thus altering its chemical properties and properties to meet specific requirements.