- Tel: +8617660708369

- Email: [email protected]

- Hebei Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

![]() Whatsapp :+86 17660708369

Whatsapp :+86 17660708369

![]() Email : [email protected]

Email : [email protected]

| GB | ISO | ASTM | JIS | ||

|---|---|---|---|---|---|

| TU1 | Cu-OF | C10200 | C1020 | ||

| T2 | Cu-RTP | C11000 | C1100 | ||

| TP1 | Cu-DLP | C12000 | C1201 | ||

| TP2 | Cu-DHP | C12200 | C1220 | ||

| GB | Composition(%) | ||||

| Cu | P | O | Other | ||

| TU1 | 99.97 | 0.002 | less than 0.002 | balance | |

| T2 | 99.9 | – | – | balance | |

| TP1 | 99.9 | 0.004-0.012 | – | balance | |

| TP2 | 99.9 | 0.015-0.040 | – | balance | |

| ASTM | Composition(%) | ||||

| Cu | P | O | Other | ||

| C10200 | 99.95 | 0.001-0.005 | – | balance | |

| C11000 | 99.9 | – | – | balance | |

| C12000 | 99.9 | 0.004-0.012 | – | balance | |

| C12200 | 99.9 | 0.015-0.040 | – | balance | |

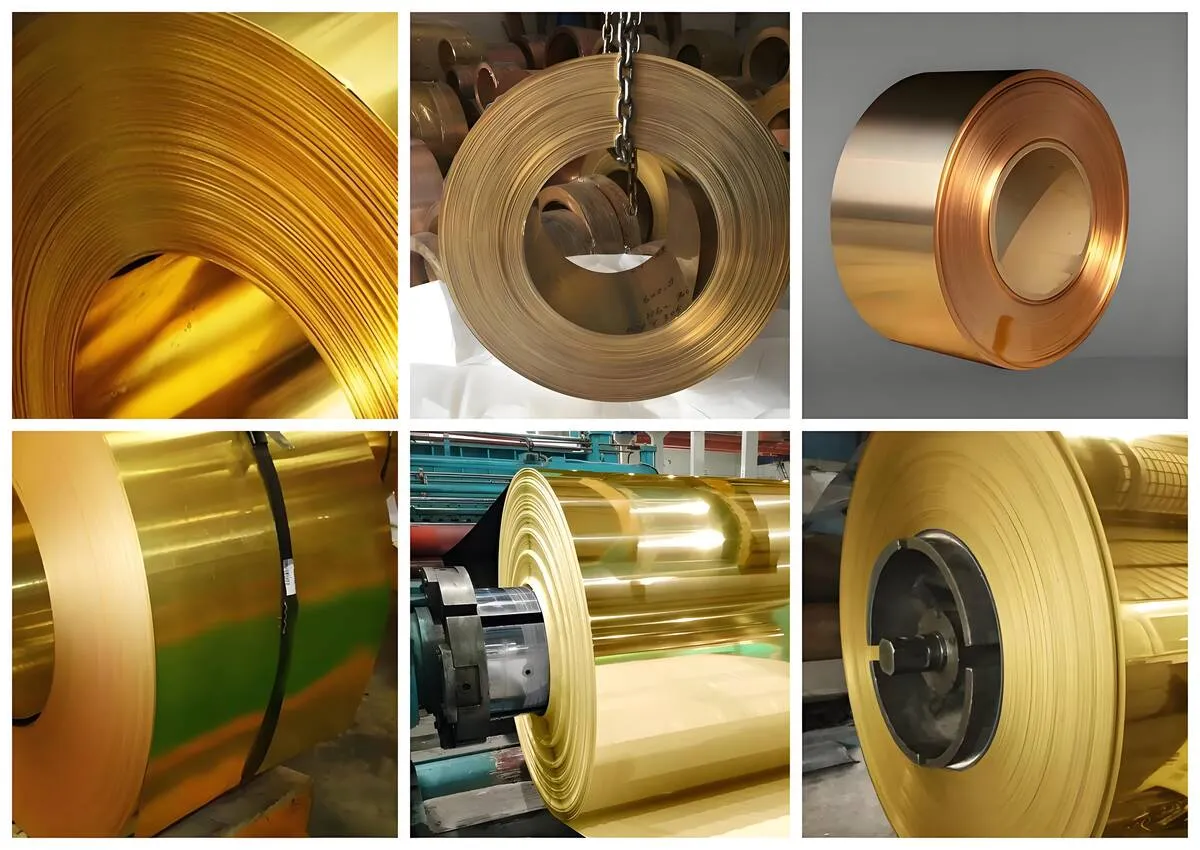

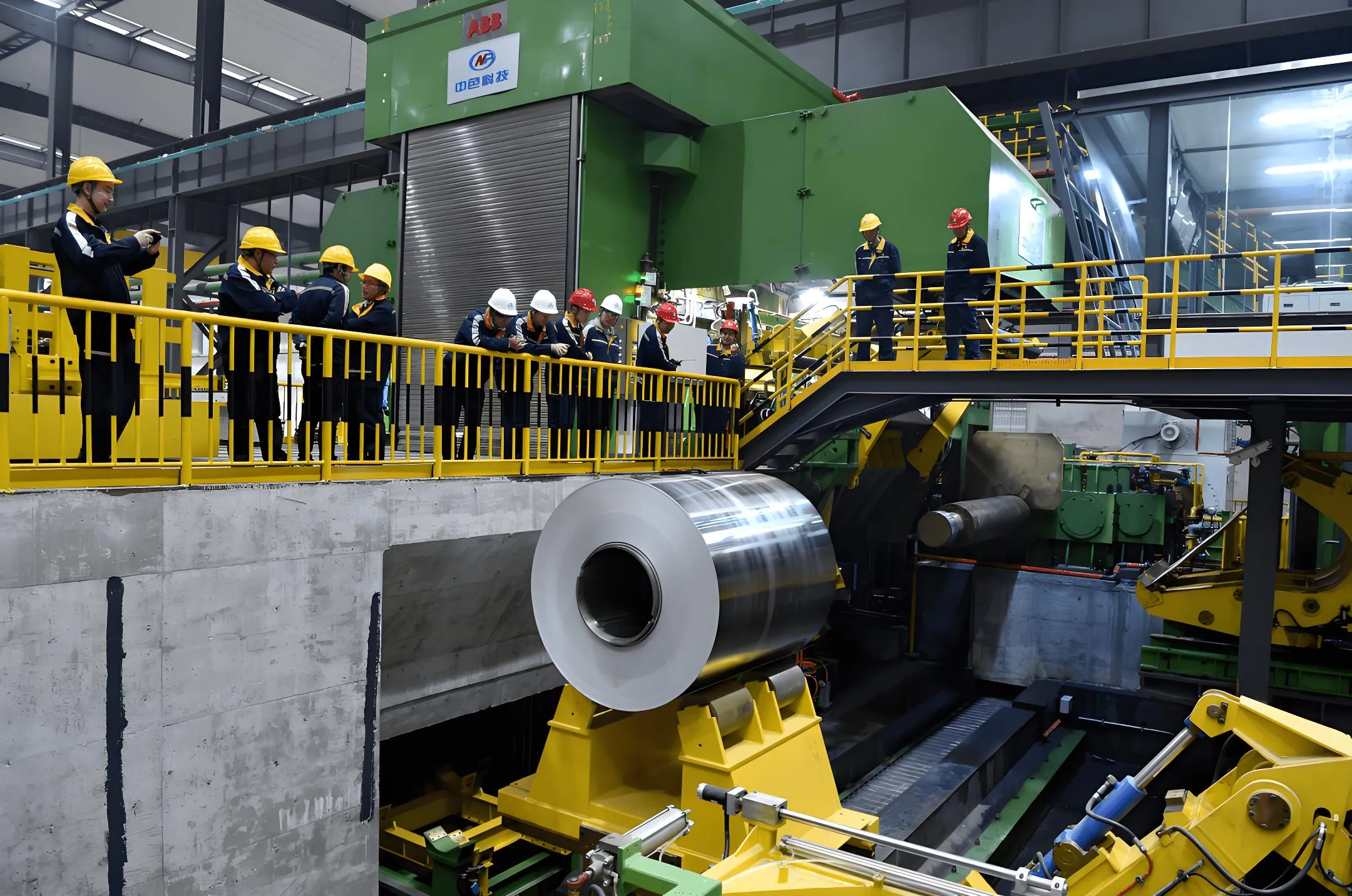

| Item | Copper Coil / Copper Strip / Copper Tape | ||||

| Standard | JIS H3100-2006 ,ASTM B152M-06,GB/T 2040-2008,ROCT 495-92,EN 1652-98,ASTM B171M-04, | ||||

| Material | C12300,C1020P,C10100,C10400,C10700,C10200,T2,C1100P,C10500,M1, | ||||

| Cu-ETP,TP1,C1201P,C11000,Cu-DLP,TP2,C1220P,C1221P,C1200,C12200, | |||||

| C14200,C23000P,H62,C2801P,C36500 | |||||

| Thickness | 0.01mm~20mm | ||||

| Width | 1mm~2500mm | ||||

| Length | Random size and customize or as required | ||||

| Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required | ||||

| Package | Standard export seaworthy or as customers’ requirements | ||||

| Application | Copper coil can be made to do all sorts of deep drawing and bending stress components,such as manufacturing pins,rivets,gasket,nuts,conduits,the barometer spring,screen,radiator parts, etc | ||||

| Export to | Ireland,Singapore,Indonesia,Ukraine,Saudi,Arabia,Spain,Canada,USA,Brazil,Thailand,Iraq,Russia,Holland,Turkey,Kuwait,Korea,Argentina,India,Egypt,Oman,Malaysia,Peru,Vietnam,Mexico,etc | ||||

1. Appearance: Usually yellow.

2. Density: generally between 8.39 and 8.53 g/cm ³.

3. Melting point: The liquid phase melting point is about 900 to 955 ° C, and the solid phase melting point is about 900 to 915 ° C.

4. Coefficient of thermal expansion: about 10-6/19 to 20.8.

5. Thermal conductivity: approximately 0.29 cal/cm ²/cm/sec.

6. It has a certain degree of ductility and can be changed by machining.

1. Corrosion resistance: It generally has good corrosion resistance in the atmosphere, fresh water, and seawater.

2. Brass is easily oxidized at high temperatures, forming an oxide film on the surface.

3. It can react with some acids, but the reaction rate is relatively slow.

4. Brass is a copper-zinc alloy, and the stability of its composition ratio affects the stability of its chemical properties to a certain extent.